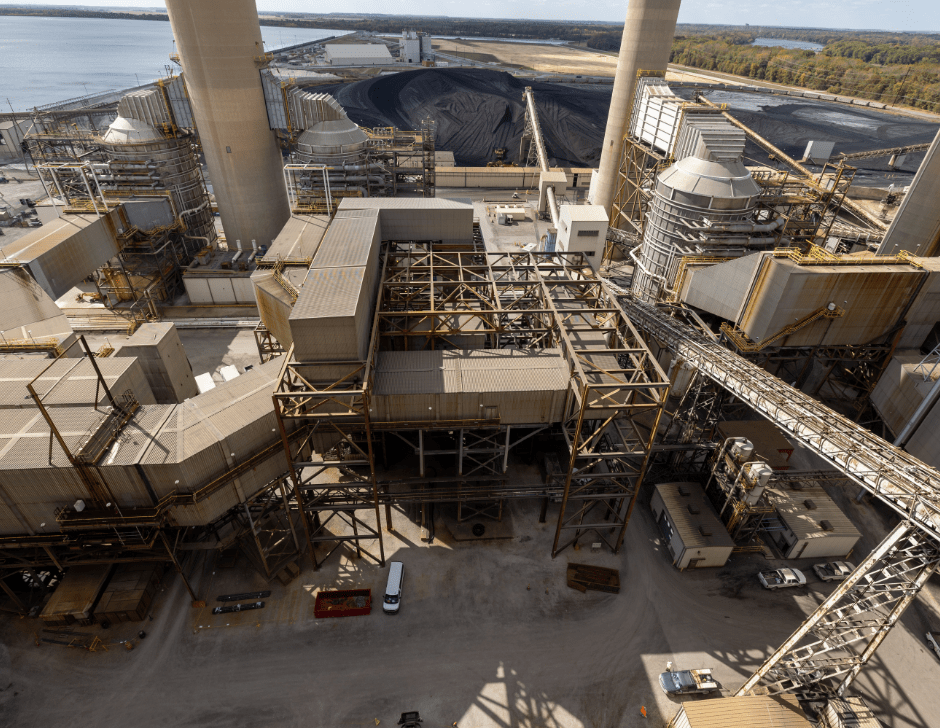

Duke Energy, Maintenance and Capital Projects

Our team maintains site office and fabrication facilities, tools and equipment, supervision, and a core group of craftsmen onsite at Duke Energy’s Gibson Station to execute routine and emergent maintenance projects. We continually adjust craft manpower levels and onsite supervision, as needed, during outages and capital projects. Our team also mobilizes to Cayuga, Madison, Woodsdale, and Wheatland Peaking Stations, as needed, for outage and capital project work. We are proud to be Duke Energy’s maintenance provider over the plant’s ammonia system and have held the specific PSM pipefitter crew contract for the past six years.

Other notable projects include:

- Dry Fly Ash Conversion

- Dry Bottom Ash and Water Redirect

- Integrated Gasification Combined Cycle (IGCC) Facility

- Selective Catalytic Reduction (SCR)

- Baffle Silencer Replacement

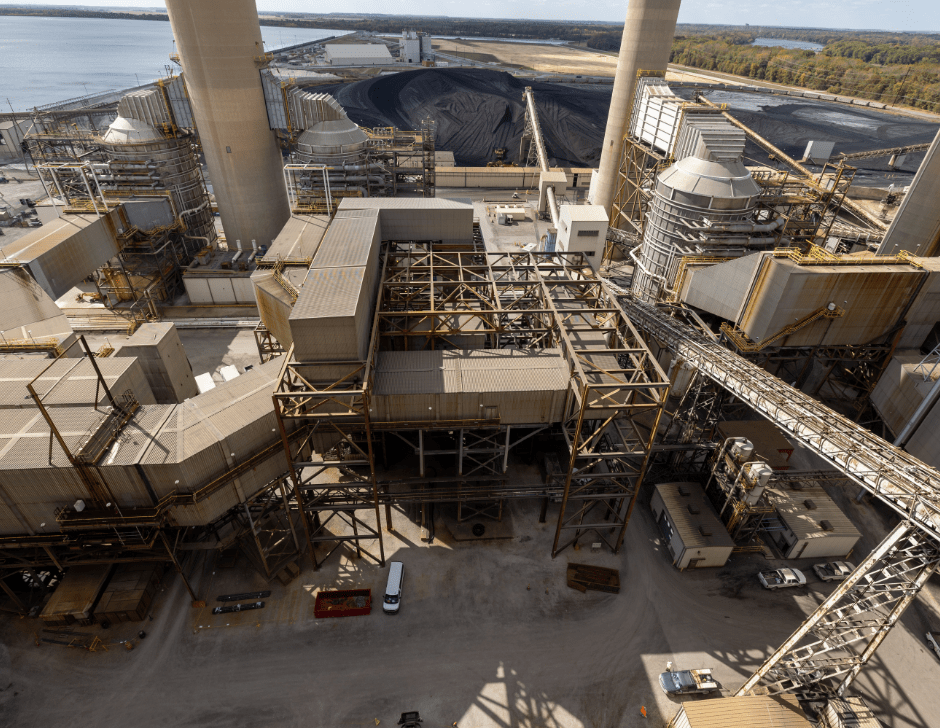

Duke Energy, Maintenance and Capital Projects

Our team maintains site office and fabrication facilities, tools and equipment, supervision, and a core group of craftsmen onsite at Duke Energy’s Gibson Station to execute routine and emergent maintenance projects. We continually adjust craft manpower levels and onsite supervision, as needed, during outages and capital projects. Our team also mobilizes to Cayuga, Madison, Woodsdale, and Wheatland Peaking Stations, as needed, for outage and capital project work. We are proud to be Duke Energy’s maintenance provider over the plant’s ammonia system and have held the specific PSM pipefitter crew contract for the past six years.

Other notable projects include:

- Dry Fly Ash Conversion

- Dry Bottom Ash and Water Redirect

- Integrated Gasification Combined Cycle (IGCC) Facility

- Selective Catalytic Reduction (SCR)

- Baffle Silencer Replacement